Process Integration and Waste Heat Recovery

Services

Services Process Integration and Waste Heat Recovery

Process Integration and Waste Heat Recovery

Process Integration and Waste Heat Recovery

Chemical Process Industries (CPI) consumes lots of Energy. The Energy usage is for Heating, Cooling, and Electrical Power.

Conventional attempts to reduce energy mainly focused on individual piece of equipments/units. Process Integration (PI) involves a systematic “Total site -as a whole” approach towards use of Heating/Cooling Requirements, electrical power and water. Thus PI ensures maximum benefits by providing alternative designs and road maps for long term energy savings.

Having executed Few Heat Integrated Distillation units and combining Reactions and downstream processing Synergy is poised to take more such jobs. Though PI covers a wide area we at Synergy would focus mainly in Facilities where Distillation consumes major energy, and where lots of waste energy is available.

Reactions like Nitration, Oxidations and Hydrogenations evolve a lot of heat due to exothermic nature. Generally the distillation or other downstream operations to these reactions consume lots of heat. The idea of having continuous processing of such reactions and utilizing the heat evolved in downstream operation integrates the process that can result in significant savings and safe operations. Synergy can help you migrate from batch reactions to continuous ones by piloting the whole process till commercial levels.

Basically PI is in use at bigger plants. Our idea is to make it work in smaller plants.

Synergy Methodology

- Simulation services to generate Heat and Material Balances

- Identify alternatives by energy analysis

- Make changes in processing conditions

- Redesign equipments in the light of above changes.

- Analyze cost data and finalize proposal.

- Execute the changes with Partners.

Waste Heat Recovery Units (WHRU)

Waste heat found in the exhaust gas of various processes or even from the exhaust stream of a process/conditioning units can be used to generate useful heat and reduce fuel consumption.

There are many different commercial recovery units for the transferring of energy from hot medium to cold one:

- Recuperators

- Regenerators

- Heat pipe exchanger

- Economizers

- Heat pumps etc

Combined Heat and Power (CHP)

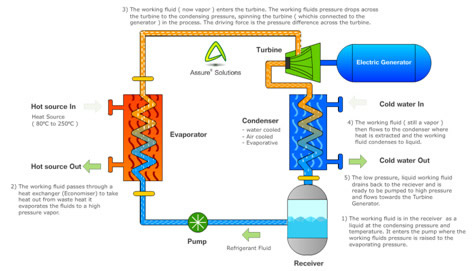

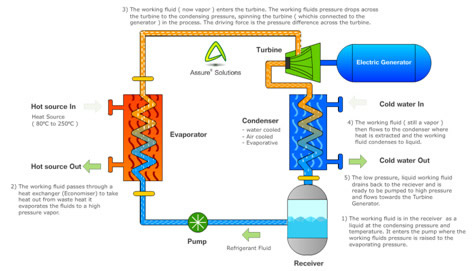

Waste heat of different degrees could be found in final products of a certain process or as a by-product in industry such as Flue gases, the slag in steelmaking plants. Units or devices that could recover the waste heat and transform it into electricity are called CHPs. Such units, for example, use an Organic Rankin Cycle (ORC) with an organic fluid as the working fluid. The fluid has a lower boiling point than water to allow it to boil at low temperature, to for a superheated gas that could drive the blade of a turbine and thus a generator.

Along with our Partners we offer

- PI/Energy analysis solutions

- Batch to Continuous Processing Migration

- Waste Heat Recovery -Simple Solutions involving heat recoveries only.

- Waste Heat Recovery- Comprehensive solutions including CHP ( Combined Heat Power)